AUTOTRANS SYSTEMS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to AUTOTRANS SYSTEMS

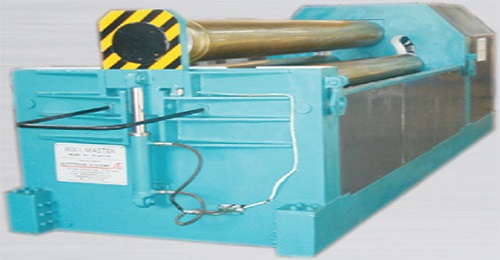

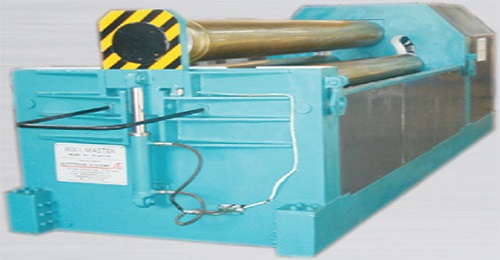

Roll Fixed Axis Plate Bending Machine

As shown the machine is most suitable as a replacement to conventional plate bending machine where pre bending is done manually or on press machine outside and then inserted to machine for rolling purpose. The machine is most economical model among all plate bending machine and is most useful for small fabrication shop as well as the shop having separate press machine on which pre bending can be carried out. Since this is a rolling only machine all the power is available for rolling purpose and one can roll smallest possible diametrer for heavy thickness plate material. The same machine can also used for plate straightening machine for small left over rolled material which is to be reused after straightening. Also rerolling is easily possible in this machine which enables apple effect correction and out of roundness correction to make it a perfect circular shape to component.

Standard Featues

Both the bottom rolls are driven rolls

All rolls are mounted on heavy duly ball bearing .Total 4 bearing per roller

Fully hydraulically operated machine requires less input power compared to electro hydraulic

Separate digital roll position meter for each side of roll makes it easy to maintain parallelism between top and bottom roll

Extra heavy central support with bearing to resist point load on roller and for longer roller life

Hydraulically operated drop end frame for ease of job removal

A single person can operate the machine while rolling

Optional Features

Hardened rolls up to 52-55 RC

Tilt able top roll for ease of removal 0of duly rolled shells

Cone bending arrangement between bottom rolls for smaller diameter cone rolling

Extra heavy cone bending arrangement on frame for bigger diameter cone rolling

Electrical control panel with moving trolley for all around access to operator

PLC controls for automatic bending and rolling

All 3 rolls positively driven for thin material rolling

Extended shaft for section rolling die mounting for rolling of section like angle, channel, beams, flats, pipes, bar etc.

Advantages

Specially developed low cost economical hydraulic systems a perfect machine for small engineering work shop

Since the top roll is moved with hydraulic pressure the rolling defect like ovality,apple effect correcion is easily possible.

Due to more power available by hydraulic systems the cycle can be completed in single pass or with minimum no of passes reducing overall operation timefor rolling.

Variable speed of rolling for slow speed for heavy plate thickness rolling and vise a versa.

Only single person can operate machine after plate feeding and up to rolled shell removal.

Small engineering workshop willing to invest less still automate rolling .

Open type rolling requiring mass production qty.

Can use as a straightening machine for pre formed material for reuse

Can use where different operations like pre bending, rolling, material straightening ,Conical rolling, section rolling need to be carried out in single machine.

Optional Features

Hardened rolls up to 52-55 RC

Tilt able top roll for ease of removal 0of duly rolled shells

Cone bending arrangement between bottom rolls for smaller diameter cone rolling

Extra heavy cone bending arrangement on frame for bigger diameter cone rolling

Electrical control panel with moving trolley for all around access to operator

PLC controls for automatic bending and rolling

All 3 rolls positively driven for thin material rolling

Extended shaft for section rolling die mounting for rolling of section like angle, channel, beams, flats, pipes, bar etc.

Application

Railway: water tank, tankar, coach bogie wall profile bending/rolling Automobile: silencers, fuel tanks, mufflers',

Offshore: drill rings

Storage: silos,tanks,

General engineering: Pressure vessal,boiler, tanks, piping, filter body

th moving: Excavator bucket, road roller drum, mobile compactors

Roll Planetary Axis Plate Bending Machines

The three roll planatory axis is a three roll machine having pre pinching/pre bending facility within the machine. The plate can be inserted from one side and is clamped between top roll and one of the pressure roll for a firm grip and the another pressure roll advances further to form desired radious of shell. The same procedure is repeated but on another side of plate to form desired radiouse. After having done pre pinchind the plate is formed in to circular shape by rolling and further pressing of pressure rolls and by forward and reverse movement of rotation by rolls. Usually a shell is formed in multiple passes of rolling by forward and reverse movement of rolls in rotary motion. It is also possible to form shell in a single pass provided the pressure roll position is well known for particular size of shell rolling by regular practice and experience. The PLC based machine is most suitable for repetitive type of jobs and shapes required regularly Other shapes can also be forme in this machine in single pass like square, polycentric,elliptical or open rolling.

Standard Featues

All 3 rolls are positively driven by in line mounted planetary gear box and hydraulic motor Roll parallelism maintained by solid linkage mechanism

Digital display for roll position for ease of rolling and for fast rolling of repetitive type components

Spherical roller bearings are used as standard in all our models

Heavy duty reinforced steel frames duly stress relieved and epoxy painted after sand blasting

Optional Features

Electronic proportional balancing using hydraulic system specially developed for plate bending a machine

Induction Hardened rolls for 52-55 RC hardness

Conical bending device

Provision for section rolling

Section bending dies

Overhead support

Lateral support

Auto plate squaring reference stopper

Tilt able top roll

Automatic roll speed compensation

Advantages

More suitable for small engineering work shop where bending requirement in small quantities and in different sizes as per job requirement

Less costly compared to 4 roll machine, hence low initial investment

Both leading and trailing edge can be pre bend in single pass. No need to remove and reinsert material

Small engineering workshop willing to invest less still automate rolling

Open type rolling requiring mass production quantity

Can use as a straightening machine for pre formed material for reuse

Can use where different operations like pre bending, rolling, material straightening ,Conical rolling, section rolling need to be carried out in single machine.

Application

Railway: water tank, tankar, coach bogie wall profile bending/rolling Automobile: silencers, fuel tanks, mufflers',

Offshore: drill rings

Storage: silos,tanks,

General engineering: Pressure vessal,boiler, tanks, piping, filter body

th moving: Excavator bucket, road roller drum, mobile compactors

Roll Variable Axis Bending Machine

As the name indicates the variable axis plate bending machine have all 3 rolls which changes its axis as per rolling needs. The top roll moves up and down and both side rolls move in and out horizontally giving advantage of reducing bottom roll centre to form small diameter and medium thickness shell rolling and also by increasing bottom roll centre one can roll large diameter and heavy thickness shell. The another main advantage of machine is that the working height is much less compared to 3 roll/4 roll planetary axis machine. Also mac hine up to capacity of 50 mm plate bending may not need any foundation. The variable axis machine can also work as a press for plate straightening application and is also capable to roll conical shapes to almost 80% values that of machine specified capacity by using it as press.

Standard Featues

All 3 rolls can be inclined on both the side

Top roll positively driven through directly mounted gear box and hydraulic motor

Hydraulic brakes for bottom rolls to avoid any slippage of material while rolling

All rolls are mounted in heavy duly ball bearings

Heavy duty reinforced steel frame duly stress relieved and epoxy painted

Roll parallelism maintained by use of proportional valves and specially developed hydraulic system.

Heavy duty travelling central roller support

Automatic force lubrication

Optional Features

All 3 rolls can be positively driven

Automatic roll speed compensation

Induction hardened rolls hardness up to 52-55 RC

Conical bending device for small reduced side bending/ rolling

Advantages

Plate material is always horizontal which makes it safe to work with this type of machine.

Lower working height due to different type of machine working principle

No need of machine foundation up to 50 mm plate rolling

Cone bending capacity is up to 80 % of banding capacity by shift and press method and since all three rolls are tilting rolls.

The top roll works as a press which enables plate straightening also

Due to machine geometry it is possible to roll higher capacity material by increasing bottom roll centre distance

Application

Railway: water tank, tankar, coach bogie wall profile bending/rolling

Automobile: silencers, fuel tanks, mufflers

Offshore: drill rings

Storage: silos,tanks

General engineering: Pressure vessal,boiler, tanks, piping, filter body

Earth moving: Excavator bucket, road roller drum, mobile compactors

Three Roll Section Bending

The latest in the 3 roll section bending machine design which gives advantage of 4 roll machine ( the bottom roll workind as a pinch roll) which enables clamping of sections at the centre between top and bottom roll to reduce distance between pinch roll and bending roll. Due this working principle of machine the straight portion of section is at minimum which increases effective material utilisation.

Standard Featues

Both the bottom rolls are positively driven by palnatery gear box and hydraulic motor directly mounted in line with roll shaft

The swinging control console gives liberty to operate machine from front or from one side which also makes it possible to remove rolled sections from front without any problem.

All our section bending machine model comes with roller mounted in ball bearing which reduces friction and enhanced torque is available for rotation which other wise will go to waste if plain bush are use which create lot of friction due to metal to metal friction.

All our machine has 2 digital meter to ascertain both the roll position and by maintaining same values one can get repetitively same size of rolling

Optional Features

All 3 rolls positively driven

Electrically operated control console for machine operation from a distance

PLC with HMI for automated component bending/rolling cycle.more than 100 rolling cycles can be saved and recalled at any given time .

Force lubrication system.

Section feeding and locating device

Hold bra

Electromechanical Plate Bending Machines

Description / Specification of Electromechanical Plate Bending Machines

We are involved in offering a wide range of Electromechanical Plate Bending Machines to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Electromechanical Plate Bending Machines. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Semi Hydraulic Plate Bending Machine

Description / Specification of Semi Hydraulic Plate Bending Machine

We are involved in offering a wide range of Semi Hydraulic Plate Bending Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Semi Hydraulic Plate Bending Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Fully Hydraulic Plate Bending Machine

Description / Specification of Fully Hydraulic Plate Bending Machine

We are involved in offering a wide range of Fully Hydraulic Plate Bending Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Fully Hydraulic Plate Bending Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Hydraulic Plate Bending Machine

Description / Specification of Hydraulic Plate Bending Machine

We are involved in offering a wide range of Hydraulic Plate Bending Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Hydraulic Plate Bending Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.